WATER GLASS-ESTER-PROCESS

In the field of mould production it is already known that water glass binder systems can be cured by adding a fluid ester hardener. Currently limited to small scale applications, in future the process will certainly become more widespread.

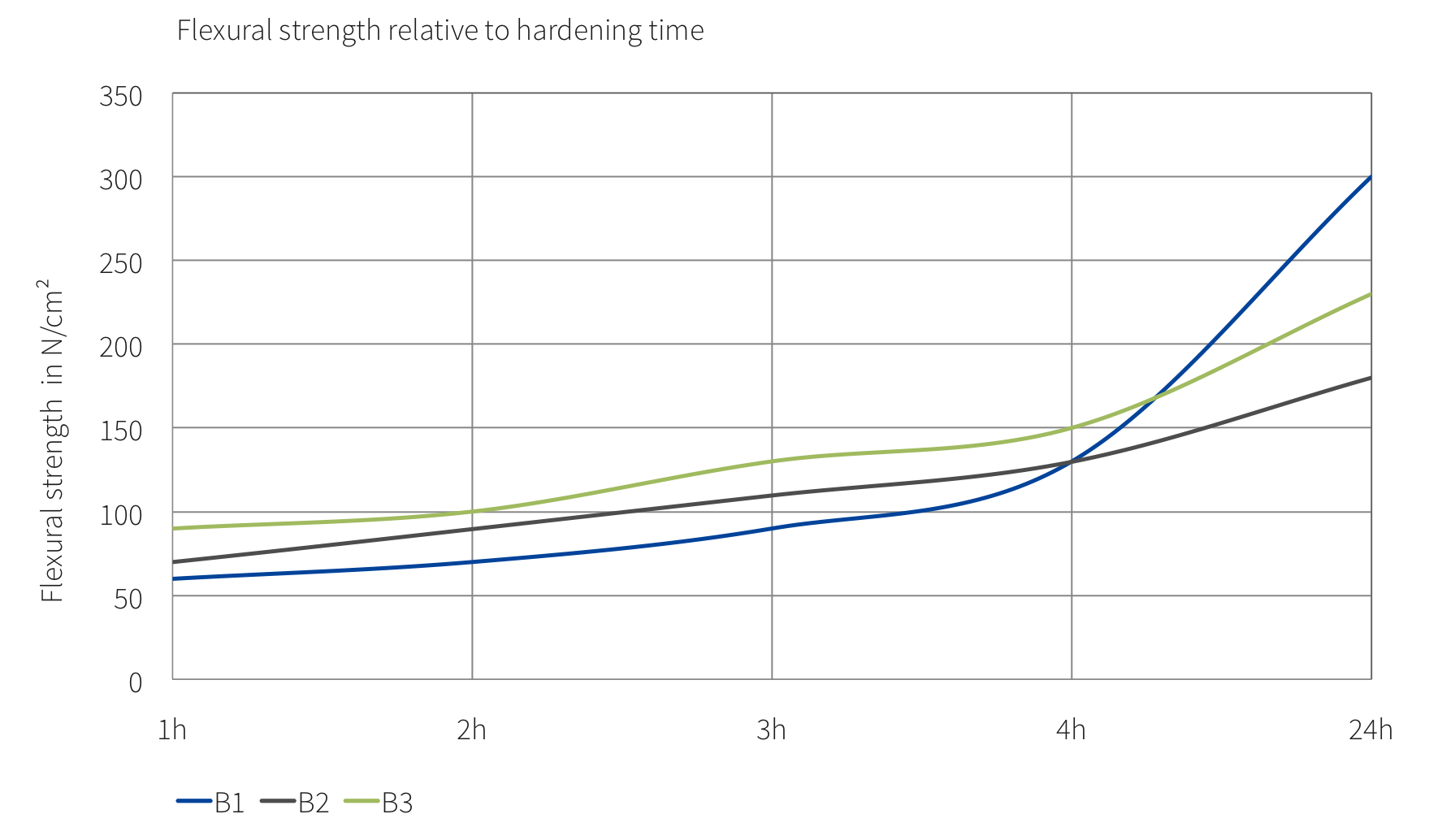

Present studies indicate that binder contents of 3% can achieve an end rigidity of between 200 und 300 N/cm2. As this is sufficient for many applications, a reduction in binder content can achieve further technological and economic advantages. A whole spectrum of hardeners with different processing times completes the product range. By combining different binders and hardeners optimal variants for all casting materials and technological requirements as well as variable ambient temperatures can be ensured.

Flexural strength of self hardening Cast Clean®- moulding mixtures (2.5 % Binder)